1.1 BPA is designed for:

– control the communication line and managing devices of the alerting system and control evacuation of people in case of fire;

– control and start of automation control cabinets (signals "Failure", "Emergency", "Automatics disabled" and " smoke exhaust Fan (pump, lock) activated);

– control and service fire automatics powered by 12 V or 24 V;

– transmission of signals through an intermediate relay device to the in-puts of elevator controllers, voice alerting units, etc.);

– control through the built-in two AL (Zone 1 – Zone 4) of addressable fire detectors, intrusion, technological devices (including those powered by AL) and transmission of notifications via SLC through RPA to the Control Panel.

1.2 BPA is designed to operate in SLC formed by RPA.

1.3 The number of BPAs registered in the Control Panel is up to 96 pcs.

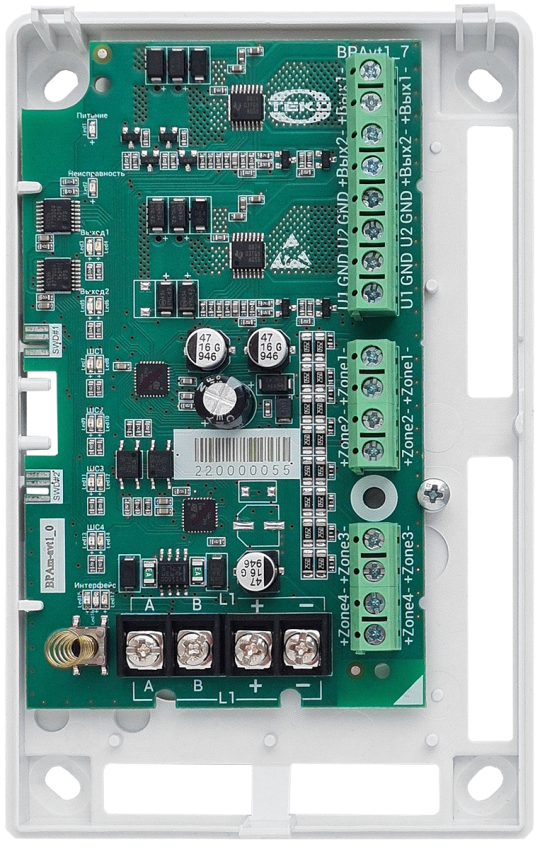

1.4 BPA provides protection of control outputs OUT1, OUT2 against overloads, polarity reversal, voltage surges.

1.5 In the initial state, reverse polarity voltage is applied to the outputs of the BPA, it is necessary to protect the connected load sensitive to polarity from reverse voltage.

1.6 The outputs OUT1, OUT2 can be operated with or without control of the integrity of the line (depending on the configuration).

When outputs are operated with line integrity control, it is necessary to connect the terminal elements of the output from the delivery set to the terminals OUT1, OUT2.

1.7 BPA provides:

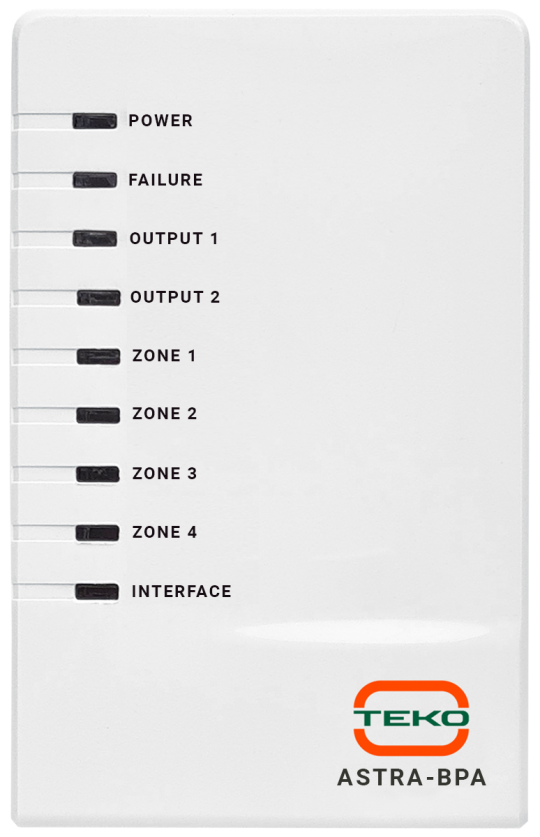

a) control of the power supply at the inputs U1, GND, U2, "+", "-";

b) switching the input voltage from 10.5 to 28.7 V from inputs U1, U2 to outputs OUT1 and OUT2 with switching current of each output up to 1.25 A;

c) control of the load line of the outputs OUT1 and OUT2, separately for open and short circuits, and transfer to the Control Panel infor-mation about the integrity of the load line;

d) control of the state of 4 alarm loops of the following types: security, fire thermal with double actuation, fire smoke with double actuation, fire com-bined with single actuation and technological with short circuit (Open cir-cuit) control;

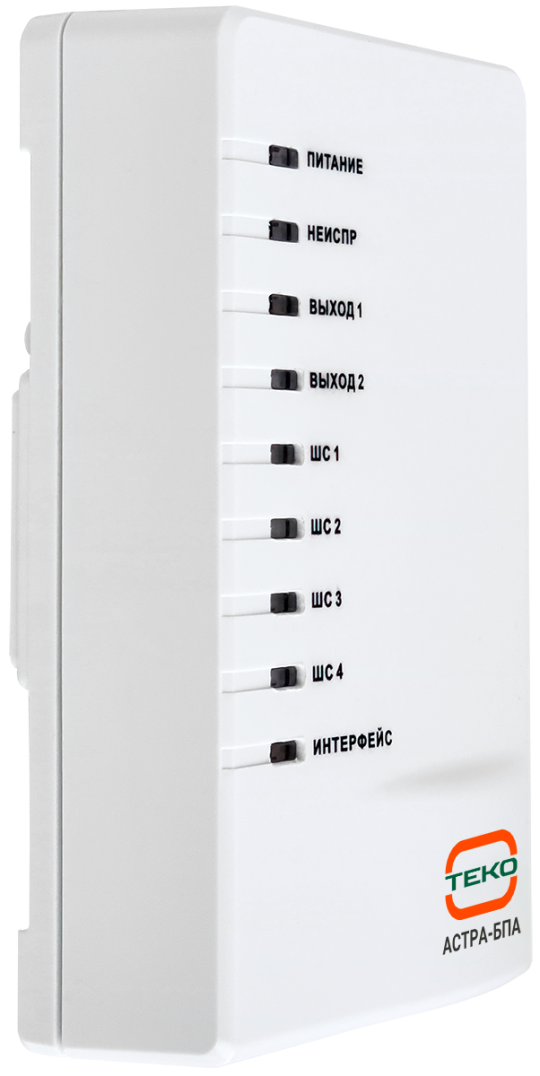

e) light indication of the BPA operation, the status of the outputs, SLC and AL.

1.8 The power supply of the address part of the BPA is carried out only from the RPA via the SLC power line (terminals "+", "-").

1.9 The power supply of the outputs and AL of the part (outputs, AL) is carried out only from an external power supply of 12 V or 24 V D.C.

.png)